We are pleased to inform you that M/s Anest Iwata Motherson Ltd.,are Manufacturers of Oil Lubricating, Oil Free and Scroll Air Compressors, in the ranging from 0.5HP to 30HP. M/s Anest Iwata Motherson Ltd., (AIML) is a joint venture between Anest Iwata-Japan, a world leader in the Lubricated, Oil Free and Scroll compressor and Sumi Motherson Group, an Indian conglomerate with presence in various sectors. These Compressors are being manufactured in a State-of-the Art plant in India and Complete know how for design & manufacturing of the compressor is provided by ANEST IWATA CORPORATION – JAPAN.

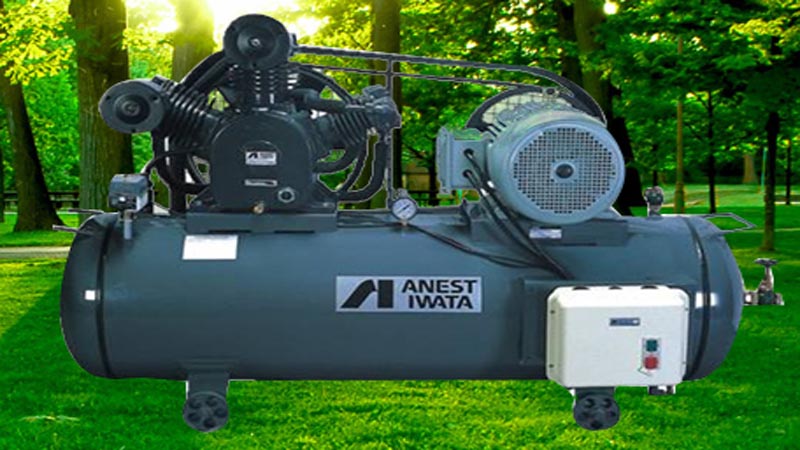

AIR COOLED RECIPROCATING, OIL LUBRICATED COMPRESSORS

Anest Iwata brand industrial air compressors in India offering “Quadra Edge Technology” oil lubricated reciprocating compressors (1 to 30 hp) having unique design features, that give it best-in class energy efficiency Significant savings in power consumption,Very less noise and vibration levels,Very less oil carry over Tried and tested in extreme Indian tropical conditions Exported all over the world including Japan and USA

OIL FREE COMPRESSOR – CMF TECHNOLOGY

Critical Maintenance Free (CMF) technology is the only of its kind in the world that gives you combination of oil free air continuous and heavy duty running and No risk of seizure. As a Patent technology of Anest Iwata, Japan, it brings in: - → Safety → Heavy Duty Operation →100% oil Free Air

SCROLL COMPRESSORS

The Scroll mechanism represents the most efficient Air compression principle and is referred as ‘The Future of Air’. It is the only compressor in the world to give the following features in a single unit;

• Guaranteed 100% Oil Free Air → Low Noise Vibration

• Energy efficiency (due to the pioneering Modular structure of scroll Compressors, Power Consumption will be equals to the Power Demand and thus ‘you pay for what you use’)

• PLC based programmable operation & predictive Maintenance

Anest Iwata compressors are subject to stringent QUALITY ASSURANCE SYSTEM at world class testing facility specially designed and manufactured to perform under the tough Industrial conditions and therefore you get the following benefits

• Air – Cooled Compressor for continuous duty application.

• Highest out put of compressor air per Hp i.e. Low power Consumption.

• Very Low maintenance Cost. →: Very Low vibration resulting in Low Noise Level.

• Desk Top Model (Used for Ventilators, Labs, Packing, Hospitals & Etc)

Our products

-

[x] Close

Air Cooled Reciprocating, Oil Lubricated Compressors

• Significant savings in power consumption

• Very less noise and vibration levels

• Very less oil carry over

• Tried and tested in extreme Indian tropical conditions

• Exported all over the world including Japan and USA

Key application areas

• Auto Workshops

• Oil/Gas Station

• Rice and Pulse Mills

• LCMS/GCMS/NMR

• Construction Segment

• Painting

• Power, Steel & Infrastructure

• Printing

• Packaging

• Brick making machines

• Fire Fighting

• Tannery

• Mining

• Sugar Plants

• Stretch Blow Moulding

• CNC/VMC machines

• Garment

• Tyre Shop

• Knitting & Hosiery

• Pollution Control Equipment

•General Industry

-

[x] Close

Air Cooled Reciprocating Oil Free Compressors

• Unique seizure free composite resin technology

• Patented Critical Maintenance Free (CMF) Technology

Features

• Patented Composite Piston

• Dynamic Balancing of Bare Compressor Assembly

• Effective Cooling

• Continuous Duty Running in Indian Ambient Conditions

Benefits

• Oil-Free, Critical Maintenance Free Machines. Safest in their Range

• Low Vibration

• Temperature Reduction

• Technology, Durability and Clean Air – at the Best Value Available

Key Application Areas

• Rice , Flour & Dal segment

• Nitrogen Generator Segment

• Spray Gun Segment

• Consultancy -Power Plants

• Printing & Packaging Segment

• Metrological Equipment -CMM etc .

• Hospitals

• Pharma -R&D and Manufacture

• CNC Machine Segment

-

[x] Close

Air Cooled Scroll Type, Oil Free Compressors

• Energy efficient compressors

• 100 % Oil free air

• Relatively low noise – 58 db for 20 HP compressor

• Can be installed in the factory floor itself – reduced pressure loss and piping costs

• Low maintenance frequency

Scroll's Uniqueness Applications Critical Requirements Advanced Features No Human/Product Contamination (100% Oil Free Air) No Oil Related Breakdown Low Noise & Vibration No Oil Related Rejections Energy Efficient (Low Pressure Drop) Energy Efficient (Variable Output) CNC Machines with Pneumatic Operations

Instrumentation and R&D Analysers

Colour Sorting

Semiconductor Manufacturing

Air Bearings

Food Processing

Beverage Processing

Garment Manufacturing

Glass Coating

Digital & Offset Printing

Hospitals

Dental Clinics

Laboratories

Nitrogen Generators

Paper Manufacturing

Pharmaceuticals Manufacturing

Premium Spray Painting

Cosmetics Manufacturing

Rubber & Leather Processing

Vacuum Metalising

-

[x] Close

High Pressure Compressor

• Higher efficiency resulting in higher FAD as compared to competition

• Very less noise and vibration levels

• Air cooled compressor resulting in longer life of parts and prevention of hassles of water cooling arrangement

• Very less oil consumption which is a unique technology feature in all AIM compressors

• Suitable for continuous duty running in extreme Indian conditions